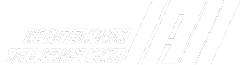

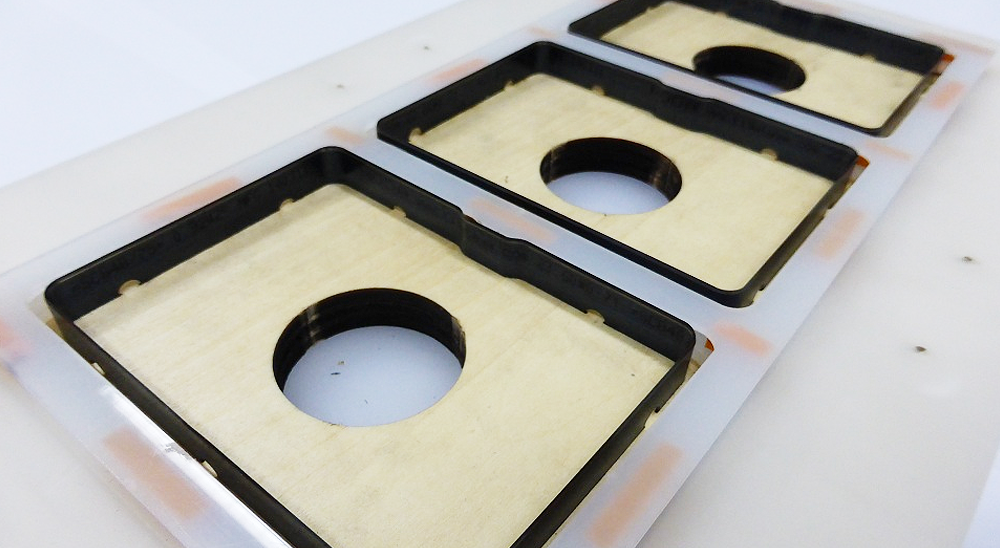

Electric Parts

Main Materials of Punching

Films (all types); Sponge; Double sided tape

Points about design, material selection and manufacturing

Because most of the parts are to be incorporated into precision instruments, we need high precision quality. In order to realize high precision, not only technical capabilities but also facilities and know-how are necessary.

Noda has abudant knowledge and experience, such as not only improving technical capabilities and equipment but also elimating defects that arise in processing designs and adhesion materials that take the finish into account. As a result, it is possible to manufacture a die which can flexibly respond to customer's request.

Electronics industry is characterized by severe demands, many who are suffering from problems such as delivery time, dimensionla accuracy, unevenness in height, adhesion countermeasures, etc. We may propose our original etching tool "Chrome Die" to request for dimensional accuracy at the seems impossible or in a percentage to help electronics industry excel in their field.

Printing

Main Materials of Punching

Tack paper, sticker, etc.

Points about design, material selection and manufacturing

Like paper containers, we often receive CAD data, but we often keep actual printed matter, in which case we check the shape of the payment data and the actual printed matter, pitch deviation etc. We often make half cuuts, we are making manufacturing pursuing height accuracy so that it is easy to use as a wodden pattern against half cuts.

In addition because there are many short-term delivery correspondences, it is often that you feel great merit on the delivery date in response to delivery.

Packaging

Main Materials of Punching

Paper, Printing box, cardboard box, plastic cardboard, danpla boxes, and other packaging material.

Points about design, material selection and manufacturing

There are three points that we need to put strong consciousness such as “appearance”, “ease of assembly”, and “ease of putting goods”.

There were many products that must use die moulds including paper and carton boxes. In order to make thin paper boxes, cigarette boxes, greeting card, candy boxes, etc, look more appealing, the die moulds need to be used. It is an indispensable matter to know the product to be put in a box and the details of its method. We also design the mould base on the customer’s process, such as paying attention to work efficiency in post-processing such as punching processing and assembly. Therefore, it is possible to design a punching die so that customers can use it easily, and it is possible to improve the quality of products after pull out.

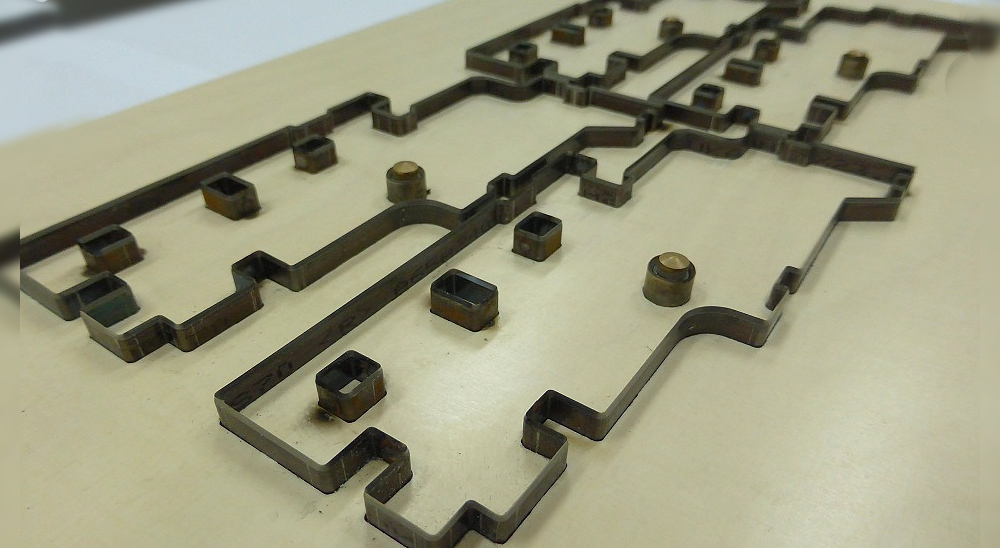

VACUUM TRAY

Main Materials of Punching

PP, PET (formed)

Points about design, material selection and manufacturing

We are making a die which can be increasing the productivity and upgrading. Do you not have any struggles with these kinds of things? When you manufacture vacuum tray of product the die of Noda is the best solution. The Vacuum formed products are used a lot in different fields such as food, cosmetics, healthcare, grocery, and component trays. Noda produces die moulds corresponding to all vacuum formed products. We are conducting the project of the 3d die mould production with the highest and most appropriate performance.

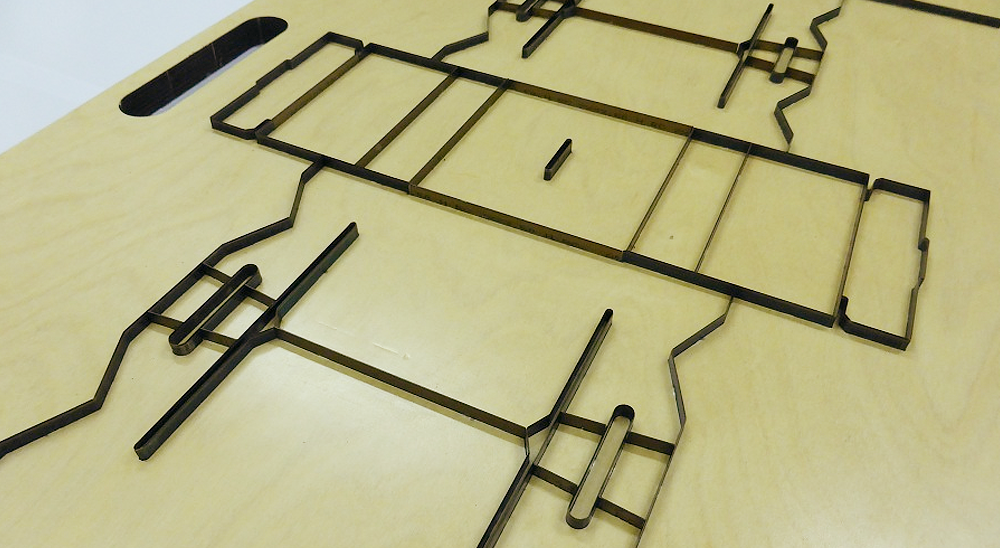

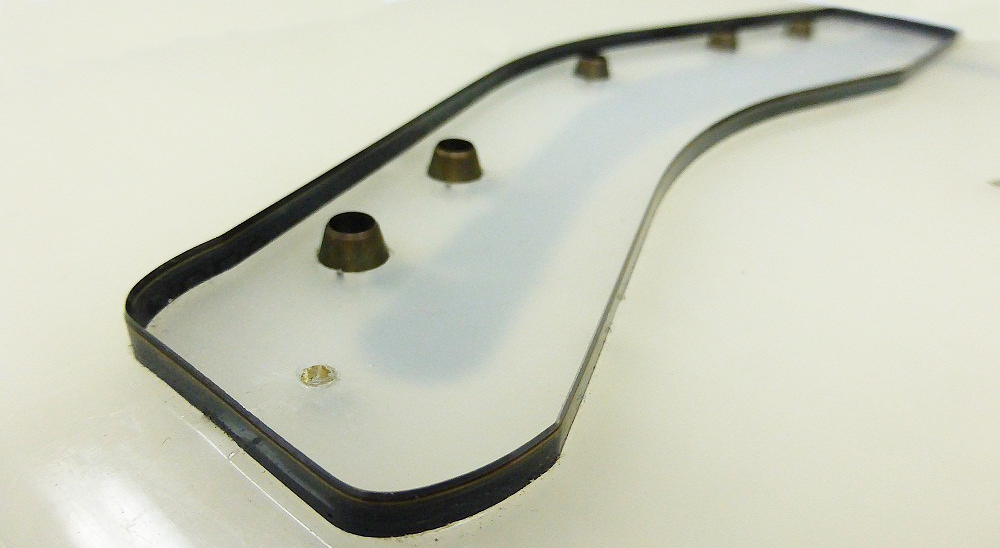

Automotive

Main Materials of Punching

Rubber, Sponge, felt, resin, joint sheet

Points about design, material selection and manufacturing

Parts used in automobiles are very numerous, and high precision is required for every part of “delivery time”, “accuracy” and “price” for each piece.

In order to realize high accuracy, not only technical capabilities but also facilities and know-how are necessary.

Originally, Noda’s main product is punching type of die for car parts. Because the cutting tools and equipment dedicated to parts processing of automobiles not available to others companies are substantial, it is possible to manufacture all types that remove soft materials from hard materials. The competitive advantage against the other companies of Noda is manufacturing products used in the automobile industry. These products require high accuracy and durability. We must select multiple types of knives, die beds and give calculations for the strength of welding joints. With our production expertise and experience, we are committed to bringing you the best products.